How to Review Your Suppliers in China: Key Considerations and Case Study

We highlight key managerial considerations to effectively review your suppliers in China and business partners in general. A case study is also presented to illustrate how outsourcing a supplier review is useful as many businesses cannot personally vet their supplier networks due to movement restrictions during the ongoing pandemic.

Anyone conducting business in China should have a clear understanding of the situation on the ground of their business partners, including but not limited to motivations and capabilities, as well as competitive position and financial and legal standing. While professional consultants can help to assess a business partner objectively, the degree of cooperation from a business partner is of paramount importance.

In any global value chain, having functioning supplier-buyer relationships is a key ingredient for successful and efficient conduct of business. In cross-border transactions and with the involvement of multiple parties in multiple jurisdictions, management capabilities take a front seat in any such venture. From large multinational organizations to small and medium-sized enterprises (SMEs), managers must ensure that communication channels are functioning, and supply chain risks are mitigated effectively.

In the following article, we will give an overview of areas that managers should consider when reviewing their suppliers or business partners in general.

Inroads for supplier review

Traditionally, larger customers perform quality and financial audits at their suppliers regularly. This, however, is not the case for many SMEs who have suppliers in China for finished goods or standardized semi-finished input products.

Lacking the political weight or financial resources, many SMEs rely on suppliers’ self-assessments or what is found during visits on business trips. The latter has become increasingly difficult with travel restriction policies adopted by countries during the COVID-19 pandemic.

Nevertheless, this article will list suggestions for supplier reviews that can be performed by local teams in a cost-efficient manner, resulting in an improved understanding of a supplier’s business, such as the business relationships, competitive pricing, potential exclusivity agreements, and operational stability of a target.

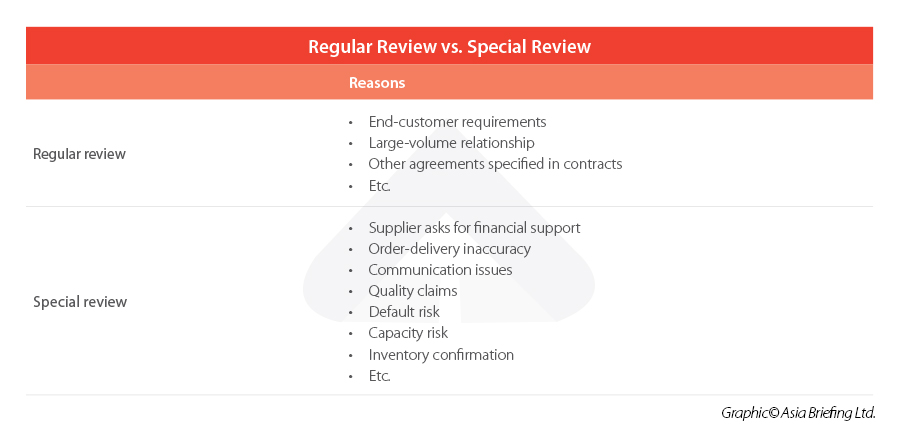

The approach for a supplier review can be via the regular or the special route.

The regular route applies to business partners that have requirements for supplier reviews in their initial agreements. Usually this is the case if the end-customer has requirements that need to be implemented throughout the supply chain, or, if a customer has a large-volume contracts with a supplier. However, there are also low volume cases with specific needs that require regular reviews in absence of end-customer requirements.

On the other hand, special supplier reviews can be initiated when there is a change in business or when irregularities occur. Such could be inaccurate delivery time or discrepancies between order and delivery.

In the same manner, quality claims, insufficient or uncertain capacity, or stocktaking are valid reasons for a special supplier review. While the pandemic disrupted global supply chains, it also opened the opportunity to review suppliers on grounds of such disruptions.

In addition, special reviews are necessary for financial changes in a business relationship.

A co-investment by the buyer or a change in the payment terms to aid a supplier’s working capital position requires financial and operational due diligence. If a customer has concerns about the solvency of a supplier but without access to accurate financial data, a visit by professionals to the recipient can help to keep a basic level of trust. However, cooperation of the supplier and the willingness to be audited on their books is necessary to gain certainty about the financial reality.

In other cases, communication issues can lead to uncertainty about future business outcomes, which can be re-assured with rather simple fact checks and objective data.

What to review?

Supplier reviews can consist of multiple sections. This can be roughly organized into operational, procedural, and administrative reviews.

Operational review

Operational review requires a visit to all production facilities that play a role in the business.

Customers should pay attention to the accuracy of what a supplier claims to be and what is found to be true. Examples are the exact size of the production facility, the production capabilities, the machinery and its operational status, material stock and material handling, inspection equipment, and personnel at each production step.

Also, the shipping area, its accurate location and protection from weather, as well as the time products remain unfinished or pre-packed in the shipping area or between production steps can hint at how quality-oriented a supplier is.

Official certificates and objective documents, like company hierarchies and process-flow charts, work instructions at the specific locations, etc. are usually part of such reviews.

A stocktaking, or inventory count is part of more time-consuming operations that requires physical visits at a designated location. It can be performed independently or in conjunction with other reviews.

Procedural review

Procedural review requires a higher degree of supplier collaboration. Vertically integrated industries, such as automotive industry, are subject to more reviews of management procedures (for example, product development, risk mitigation, etc.). The customer can review whether the supplier has standard project management procedures implemented in practice with an internal reporting system defined for each milestone.

A mechanism to flag risks occurring in the development process that could lead to product failures or simple breach of deadlines is important, too. Sophisticated factories will have a Process Failure Mode and Effect Analysis (P-FMEA) in place for production, while professional R&D departments will employ development FMEAs. Customers, however, should be cautious about the implementation of FMEAs and whether they are created and policed independently of customer requests.

Apart from above, which is usually subject to full quality audits, there are other simpler procedures. Business processes the supplier has with other stakeholders can be investigated.

One example is the material order process. How an order is placed, whether in bulk or according to demand, can reveal a supplier’s professionalism and financial prudence. The supplier should be able to show his order book and proof that his orders have been received on time. Such order-delivery accuracy will indicate if there are irregularities to be expected in your supply chain.

Another example of simple procedures that can be investigated, is the availability of production manuals and instruction for workers, as well as official technical standards necessary to understand customer requirements. Furthermore, official certificates, such as insurance policies and management certifications should be available when visiting a supplier without prior notice.

Administrative review

The third category is administrative review and can partially be conducted remotely.

Basic items a customer should review are the supplier’s business license, its business scope and registered capital, as well as the legal history of the target and changes to its business in the past. The official shareholder structure and potential non-public stakeholders can reveal how a supplier is integrated in an industry and where financial resources come from.

A second step requiring deeper investigation is the business relationships the supplier has with the customer’s competitors or major customers in other product categories. While this data is hardly easy to obtain, sophisticated suppliers will be open to disclose non-confidential relationships and provide customer references to verify their claims.

Of special interest are price benchmarks. This is not directly related to an administrative supplier review since pricing is confidential in most cases. Professional consultants, however, can help achieve clarity about market prices and the competitive position of a supplier.

Case study: On-site visit to re-establish communication channels and assess quantity & quality of ordered products

In the below case, we engaged in an operational review with selected procedural and administrative items:

One of our clients, an overseas company (hereafter “the Company”), procured main materials from China, where the Company maintained a good and cooperative business relationship with its Chinese supplier for many years.

However, the relationship was strained since 2020, when the novel coronavirus spread and disrupted global supply chains. Due to the negative impact of the pandemic, the Chinese supplier ceased export activities for several planned shipments and required contract renewal before resuming production. The supplier claimed that their factory suffered financial losses and had no financial liquidity to produce for large orders. To maintain the business relationship and receive supplies in the future, the Company was required to make high deposits to the supplier before the arrangement of production.

Given the long-standing cooperation, the Company paid part of the deposits. However, subsequent orders were neither received on time nor at an agreed quantity. Meanwhile, during video calls, the Company noticed that inventories seemed to be in poor condition, which raised further concerns of receiving faulty parts. Although inquiries to the supplier by phone were always answered timely, responses became increasingly vague and implausible.

Dezan Shira & Associates engaged to help the Company understand the reality on the ground, including the commercial and financial situation of the supplier, with the goal to re-establish the relationship between the parties based on facts and credible reasoning.

The engagement included an on-site visit with a physical stocktaking and a basic quality assessment for products to be shipped. Our team found only half the products claimed ready to ship were packed and loaded in the container, but there were no evident quality issues. It was further revealed that the underlying issues were related to input materials and could be solved within two weeks – if orders were placed timely. We reviewed the supplier’s production capacity and material orders and renegotiated a new delivery plan. Our client valued the swift results of our engagement and regained trust in his business partner.

Summary

In international business, face-to-face engagements are crucial to establish strong business relationships with functioning communication channels and swift risks mitigation. Traditionally, business trips have served to form such communication channels, while financial and quality audits have established facts. However, to overcome current issues in light of travel restrictions, supplier reviews may be outsourced and conducted on a sub-set of items tailored to individual needs, which may be distinct from full quality and financial audits. Our case study is just one example of such.

About Us

China Briefing is written and produced by Dezan Shira & Associates. The practice assists foreign investors into China and has done so since 1992 through offices in Beijing, Tianjin, Dalian, Qingdao, Shanghai, Hangzhou, Ningbo, Suzhou, Guangzhou, Dongguan, Zhongshan, Shenzhen, and Hong Kong. Please contact the firm for assistance in China at china@dezshira.com.

Dezan Shira & Associates has offices in Vietnam, Indonesia, Singapore, United States, Germany, Italy, India, and Russia, in addition to our trade research facilities along the Belt & Road Initiative. We also have partner firms assisting foreign investors in The Philippines, Malaysia, Thailand, Bangladesh.

- Previous Article China’s Tariff Exclusions for US Imports: A Timeline

- Next Article AmCham Survey Findings Show US Businesses Bullish on China in 2021